In modern logistics, where global e-commerce and high-frequency shipping have become the norm, ensuring product safety throughout transportation is no longer optional—it is a critical strategic requirement. The efficiency of a packaging system depends not only on outer packaging materials but also on the performance of the cushion packaging filler used inside the box. High-quality protective fillers reduce product damage, minimize returns, and support sustainable logistics operations.

As a professional manufacturer specializing in air cushion packaging systems, BJT Pack Group provides a complete portfolio of protective packaging solutions designed for automated warehouses, 3PL providers, and high-volume e-commerce fulfillment centers. The following analysis outlines the major types of logistics cushion packaging fillers, their technical characteristics, and the specific application scenarios where each performs best.

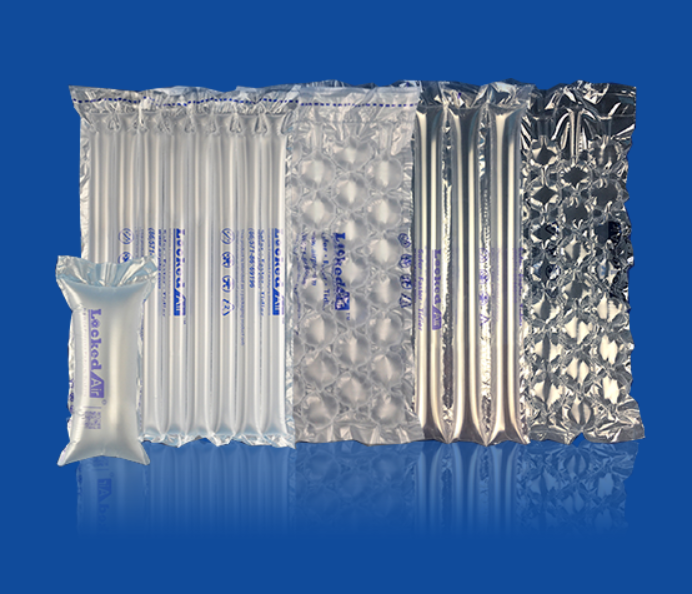

Among modern protective packaging options, air cushion packaging has become one of the most widely adopted solutions due to its exceptional cushioning performance, low material consumption, and compatibility with automated inflation systems.

Technical Features

High air retention: LockedAir uses multi-layer co-extruded films that maintain consistent internal pressure during long-distance transport.

Precision air-cell design: Each cushion distributes impact forces evenly, reducing peak stress on fragile items.

On-demand inflation: Rolls of flat film take minimal warehouse space and are inflated only when needed, improving operational efficiency.

Ideal Applications

Air cushion packaging is suitable for electronics, home appliances, personal care products, toys, household goods, and nearly all general e-commerce shipments.

For logistic centers seeking a balance between cost control and strong protection performance, air cushions remain one of the most efficient solutions.

Air pillow films—commonly used for void filling—are a core product within the air cushion packaging category.

Advantages

High-speed production: LockedAir automatic machines deliver up to 28 meters of air pillows per minute.

Stable inflation: Optimized sealing technology prevents deflation caused by vibration or temperature change.

Multiple sizes and thicknesses: Suitable for light to medium-weight goods needing simple cushioning or void-fill functions.

Use Cases

Filling empty spaces in shipping cartons

Preventing product movement during transportation

High-throughput e-commerce warehouses

For businesses with rapid packing lines, air pillows deliver the best combination of speed and protection.

Air column bags, also known as inflatable column packaging, feature a structure of individually connected air chambers. If one chamber is punctured, the others remain inflated, ensuring continuous protection.

Technical Benefits

360° wrap-around protection

Excellent load distribution

Highly customizable for product shape

LockedAir air column film can be quickly inflated with an air cushion machine to produce bottle sleeves, electronic product packs, or custom-fit protective forms.

Best for

Wine & beverage bottles

Cameras and lenses

Cosmetics and glass containers

Small appliances and electronics

For fragile, high-value goods, independent-chamber column bags provide superior drop and compression resistance.

LockedPaper Honeycomb paper uses a hexagonal cellular structure that offers strong compression strength and shock absorption while remaining biodegradable.

Performance Attributes

High structural rigidity

Good edge protection

Sustainable packaging alternative

The kraft-paper honeycomb structure absorbs external impact forces, making it suitable for medium-to-heavy products requiring environmental compliance.

Common Applications

Ceramics and glassware

Cosmetics and personal care

Electronics accessories

Premium packaging requiring a natural look

As sustainability targets increase globally, honeycomb paper becomes a preferred eco-friendly cushioning material.

LockedPaper Paper bubble wrap replaces traditional plastic bubble film with a recyclable paper-based material, offering both shock absorption and an eco-friendly product presentation.

Features

Moisture resistance and good tensile strength

Biodegradable and cost-effective

Suitable for both wrapping and light cushioning

Paper bubble wrap is widely used by brands seeking environmentally responsible packaging without sacrificing protective performance.

LockedPaper Kraft paper void fill is a versatile solution produced by automated crumpling or shaping machines, creating Z-fold, 3D-structured, or butterfly-shaped paper cushions.

Advantages

Strong internal support for heavy loads

Good compression resistance

Fully recyclable and biodegradable

Use Cases

Heavy or irregularly shaped products

Industrial components

Books, metal parts, and tools

For packaging scenarios requiring natural, renewable materials with strong void-fill capabilities, kraft paper remains one of the most reliable solutions.

Selecting the appropriate cushion packaging filler depends on product fragility, weight, logistics distance, packing speed, sustainability goals, and cost requirements.

LockedAir and LockedPaper provide a full range of air cushion packaging systems and sustainable packaging materials designed for modern logistics operations. Whether you require fast on-demand void fill, precision protection for fragile goods, or environmentally friendly cushioning alternatives, each solution delivers distinct technical advantages.

By understanding the structural differences, material properties, and performance characteristics of each packaging filler type, logistics professionals and e-commerce operators can make informed decisions that:

Reduce transit damage

Lower return rates

Improve packing efficiency

Support sustainable supply chain strategies

Enhance consumer experience

The right cushion packaging strategy is not simply a protective measure—it is a key contributor to operational excellence and long-term brand value.